1、SCARA機器人

SCARA(Selective Compliance Assembly Robot Arm,中文譯名:選擇順應性裝配機器手臂)是一種圓柱坐標型的特殊類型的工業機器人。

1978年,日本山梨大學牧野洋發明SCARA,該機器人具有四個軸和四個運動自由度,(包括X,Y,Z方向的平動自由度和繞Z軸的轉動自由度)。該系列的操作手在其動作空間的四個方向具有有限剛度,而在剩下的其余兩個方向上具有無限大剛度。

SCARA系統在x,y方向上具有順從性,而在Z軸方向具有良好的剛度,此特性特別適合于裝配工作,例如將一個圓頭針插入一個圓孔,故SCARA系統首先大量用于裝配印刷電路板和電子零部件;SCARA的另一個特點是其串接的兩桿結構,類似人的手臂,可以伸進有限空間中作業然后收回,適合于搬動和取放物件,如集成電路板等。

如今SCARA機器人還廣泛應用于塑料工業、汽車工業、電子產品工業、藥品工業和食品工業等領域。它的主要職能是搬取零件和裝配工作。它的第一個軸和第二個軸具有轉動特性,第三和第四個軸可以根據工作的需要的不同,制造成相應多種不同的形態,并且一個具有轉動、另一個具有線性移動的特性。由于其具有特定的形狀,決定了其工作范圍類似于一個扇形區域。

SCARA機器人可以被制造成各種大小,最常見的工作半徑在100毫米至1000毫米之間,此類的SCARA機器人的凈載重量在1千克至200千克之間。

The SCARA acronym stands for Selective Compliant Assembly Robot Arm and is one that is hard to remember. It's also sometimes referred to as: Selective Compliant Articulated Robot Arm.

The SCARA acronym stands for Selective Compliant Assembly Robot Arm and is one that is hard to remember. It's also sometimes referred to as: Selective Compliant Articulated Robot Arm.

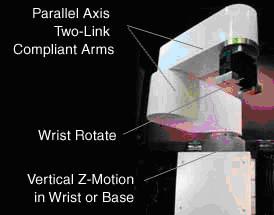

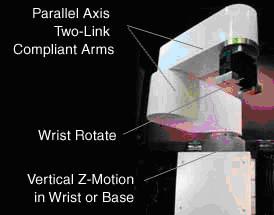

In general, traditional SCARA’s are 4-axis robot arms, i.e., they can move to any X-Y-Z coordinate within their work envelope. There is a fourth axis of motion which is the wrist rotate (Theta-Z). The ‘X’, ‘Y’ and the ‘Theta-Z’ movements are obtained with three parallel-axis rotary joints. The vertical motion is usually an independent linear axis at the wrist or in the base.

By virtue of the SCARA’s parallel-axis joint layout, the arm is slightly compliant in the X-Y direction but rigid in the ‘Z’ direction, hence the term: Selective Compliant. This is advantageous for many types of assembly operations, e.g., inserting a round pin in a round hole without binding.

The second attribute of the SCARA is the jointed two-link arm layout similar to our human arms, hence the often-used term, Articulated. This feature allows the arm to extend into confined areas and then retract or “fold up” out of the way. This is advantageous for transferring parts from one cell to another or for loading/ unloading process stations that are enclosed.

SCARA’s are generally faster and cleaner than comparable Cartesian systems. Their single pedestal mount requires a small footprint and provides an easy, unhindered form of mounting. On the other hand, SCARA's can be more expensive than comparable Cartesian systems and the controlling software requires inverse kinematics for linear interpolated moves. This software typically comes with the SCARA though and is usually transparent to the end-user

2、DELTA機器人

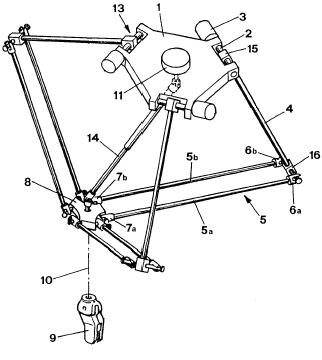

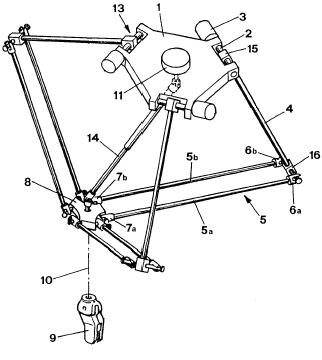

????? Delta機器人就像一個倒掛的有三個腳的蜘蛛,因其的靈巧、速度和精確在裝配、自動化和醫療設備領域得到應用。但是由于其發明專利控制在少部分人手里,Delta并沒有得到應有的推廣。最近,Delta機器人機構設計的專利即將到期,使其他制造商有機會生產類似Delta的機器人裝置。

SCARA(Selective Compliance Assembly Robot Arm,中文譯名:選擇順應性裝配機器手臂)是一種圓柱坐標型的特殊類型的工業機器人。

1978年,日本山梨大學牧野洋發明SCARA,該機器人具有四個軸和四個運動自由度,(包括X,Y,Z方向的平動自由度和繞Z軸的轉動自由度)。該系列的操作手在其動作空間的四個方向具有有限剛度,而在剩下的其余兩個方向上具有無限大剛度。

SCARA系統在x,y方向上具有順從性,而在Z軸方向具有良好的剛度,此特性特別適合于裝配工作,例如將一個圓頭針插入一個圓孔,故SCARA系統首先大量用于裝配印刷電路板和電子零部件;SCARA的另一個特點是其串接的兩桿結構,類似人的手臂,可以伸進有限空間中作業然后收回,適合于搬動和取放物件,如集成電路板等。

如今SCARA機器人還廣泛應用于塑料工業、汽車工業、電子產品工業、藥品工業和食品工業等領域。它的主要職能是搬取零件和裝配工作。它的第一個軸和第二個軸具有轉動特性,第三和第四個軸可以根據工作的需要的不同,制造成相應多種不同的形態,并且一個具有轉動、另一個具有線性移動的特性。由于其具有特定的形狀,決定了其工作范圍類似于一個扇形區域。

SCARA機器人可以被制造成各種大小,最常見的工作半徑在100毫米至1000毫米之間,此類的SCARA機器人的凈載重量在1千克至200千克之間。

In general, traditional SCARA’s are 4-axis robot arms, i.e., they can move to any X-Y-Z coordinate within their work envelope. There is a fourth axis of motion which is the wrist rotate (Theta-Z). The ‘X’, ‘Y’ and the ‘Theta-Z’ movements are obtained with three parallel-axis rotary joints. The vertical motion is usually an independent linear axis at the wrist or in the base.

By virtue of the SCARA’s parallel-axis joint layout, the arm is slightly compliant in the X-Y direction but rigid in the ‘Z’ direction, hence the term: Selective Compliant. This is advantageous for many types of assembly operations, e.g., inserting a round pin in a round hole without binding.

The second attribute of the SCARA is the jointed two-link arm layout similar to our human arms, hence the often-used term, Articulated. This feature allows the arm to extend into confined areas and then retract or “fold up” out of the way. This is advantageous for transferring parts from one cell to another or for loading/ unloading process stations that are enclosed.

SCARA’s are generally faster and cleaner than comparable Cartesian systems. Their single pedestal mount requires a small footprint and provides an easy, unhindered form of mounting. On the other hand, SCARA's can be more expensive than comparable Cartesian systems and the controlling software requires inverse kinematics for linear interpolated moves. This software typically comes with the SCARA though and is usually transparent to the end-user

2、DELTA機器人

????? Delta機器人就像一個倒掛的有三個腳的蜘蛛,因其的靈巧、速度和精確在裝配、自動化和醫療設備領域得到應用。但是由于其發明專利控制在少部分人手里,Delta并沒有得到應有的推廣。最近,Delta機器人機構設計的專利即將到期,使其他制造商有機會生產類似Delta的機器人裝置。

)

![bzoj 4517: [Sdoi2016]排列計數](http://pic.xiahunao.cn/bzoj 4517: [Sdoi2016]排列計數)

)